-Fonjoy molds is a sub-factory of Ningbo Fonjoy Technology Co.,Ltd.

-The factory located in Ningbo city---One of major advanced manufacture and export base in China, also a well-known city for plastic industry, like injection machinery manufacture, plastic molds maker, and raw material trading center.

-Our factory has 1000 square meters workshop, owning CNC machine 3 sets, EDM 5 sets, drilling machine 3 sets, and other necessary equipment. Our chief engineer has 20 years experience in plastic molding field, and 3 mould designer and engineer assistant. We have two working group at workshop presence, which guarantee the working progress and complete the mould on time.

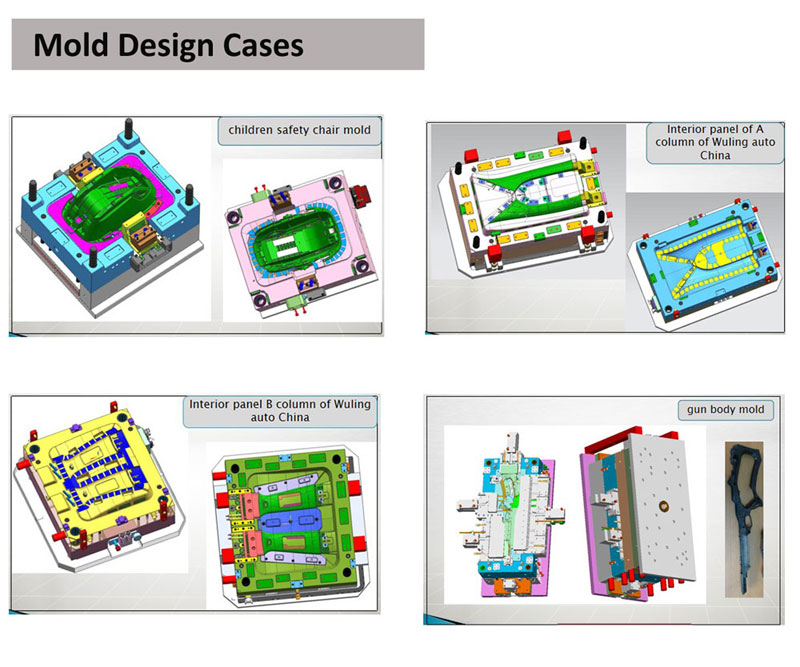

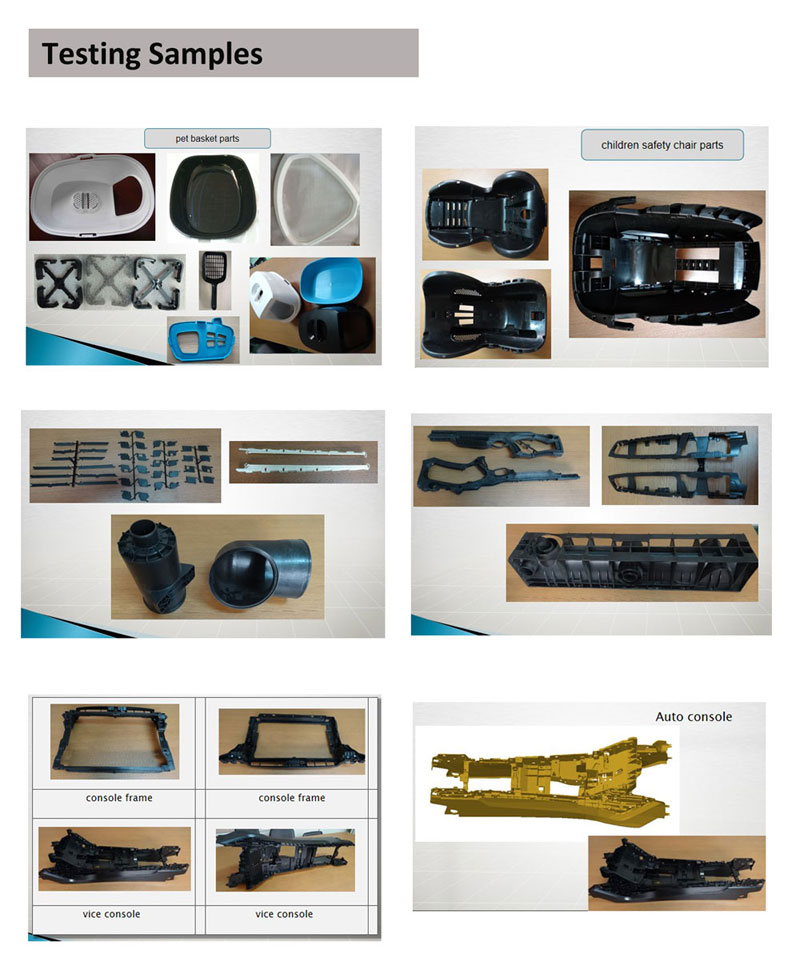

-We can make many kinds of plastic injection molds, like house ware molds,loud speaker molds, home appliance parts mold, electric tools mold, and other industrial parts mold.

Q1. How about the lead time?

A: The lead time depends on what kind of molds you ordered. Normally for small molds, it takes 5-6weeks, big molds 7-8weeks, extra big molds(e.g. size exceed 1meter) 9-10 weeks.

Q2.What’s your terms of delivery?

A: The normal term is like FOB, CNF, CIF...

Q3. What’s your terms of payment?

A: T/T or L/C at sight.

Q4. Do you provide 3D models and 2D drawing before molds making?

A:Yes, once order confirmed and deposit received, we will start to work 3D models and 2D drawing, for client’s final approval; then go to CNC works.

Q5. Can we have updates during molds making?

A: Sure, we have a tracking chart for each mold making, and send you the updates every week until the mold completed.

Q6. What’s the guarantee of your molds?

A: Actually our molds design and making is based on client’s requirement. The client should give us a quantity forecast of the molds gonna to work, then we choose mold steel, mold parts, to guarantee the lifespan.

Q7. How to maintain a mold when dismount from the machine?

A: 1) turn off cooling water, blow up the water.

2)Clean up all surface, spray anti-rust oil equally.

3)Place the mold at safe and dry position,make a record.

Q8. How can we get a fast quotation feedback?

A: In order for the maker to evaluate the molds cost precisely, the inquiry should include 2D drawing, 3D models, lifespan expectation, parts material using, parts surface requirement, and machine parameters.